Written by: Ana de la Cal, Net Zero Chemistry & Amanda Martin, Global Impact Coalition

Key take-aways:

- Methanol can be produced from a variety of feedstocks, including fossil fuels (the conventional source), as well as from more sustainable alternatives such as recycled waste products, bio-based materials and through the capture and utilization of carbon dioxide (CCU or DAC).

- The value of sustainable methanol lies in its potential to reduce emissions compared to conventional fossil-based alternatives.

- Renewable methanol from bio-based feedstocks is gaining attention, with clear opportunities to source from biomass and recovered waste materials.

- Another promising approach involves capturing and chemically converting carbon dioxide into methanol.

- Upscaling the production and usage of sustainable methanol could advance net zero carbon emission goals in both the chemical and transportation sectors.

- The Global Impact Coalition is advancing a project with the aim to scale-up sustainable methanol production and usage.

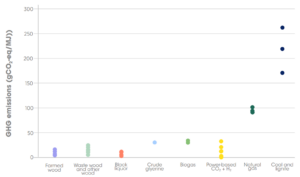

Methanol (CH3OH) is the simplest alcohol and serves as a fundamental building block for numerous everyday materials in our interconnected economy. Due to its versatility and variety of applications, methanol plays a crucial role in the value chain as a carbon source for both fuels and materials. Sustainable methanol is emerging as a promising alternative to the current fossil fuel-based sources. Sustainable methanol has significant environmental benefits as it typically has lower greenhouse gas (GHG) emissions compared to traditional fossil-based methanol (see figure 1). (However, to properly assess its climate impact, a full Life Cycle Assessment (LCA) should be conducted on the specific value chain of methanol.)

Figure 1. GHG emissions of methanol produced from various feedstocks. Source: IRENA AND METHANOL INSTITUTE (2021), Innovation Outlook: Renewable Methanol, International Renewable Energy Agency, Abu Dhabi.

Methanol Applications

Methanol is used across various industries, including in the production of plastics, paints and as a solvent. Approximately 70% of methanol is converted into other chemicals, while the remaining 30% is used as fuel for vehicles, cooking stoves, and industrial boilers.

Methanol’s physical properties make it suitable as a transportation fuel. In addition to being an excellent energy storage medium, it serves as a high-performance fuel with an octane rating of 100, capable of being blended with gasoline as an oxygenated additive. While methanol has long played a role in the automotive sector, its use as a fuel has been heavily influenced by economic factors. Today it is being explored for use in fuel cell electric vehicles.

In the chemical industry, sustainable methanol is a building block for more sustainable (low-emission, circular, bio-origin) chemicals. The production of olefins from sustainable methanol through the methanol-to-olefins (MTO) process offers a promising alternative to traditional petrochemical routes; however, this approach is yet to be used at a commercial scale.

Methanol sourcing

Methanol can be produced from a variety of feedstocks, including fossil fuels (the conventional source), as well as from more sustainable alternatives such as recycled waste products, bio-based materials and through the capture and utilization of carbon dioxide (CCU or DAC).

Renewable sources of methanol are gaining traction, with biomass and waste materials emerging as key feedstocks. Today only a limited number of industrial and experimental facilities are in operation. These sites focus on utilizing waste streams and by-products from other industrial processes as they currently offer the most favorable economic conditions.

Currently, methanol is almost exclusively produced via synthetic processes. It is made from synthesis gas or syngas, which is a mixture primarily composed of hydrogen (H₂), carbon monoxide (CO), and carbon dioxide (CO₂). It can be produced through various methods, including steam reforming of natural gas and coal gasification. The emissions from the production of methanol are significant, accounting for about 10% of overall CO2 emissions from the chemical sector.

New methods are being developed to produce methanol directly from natural gas without using syngas, as well as through the hydrogenation of CO2.

Renewable methanol from biomass, biogas or recovered waste materials

Renewable methanol, or bio-methanol, can be produced from sustainable biomass, including forestry and agricultural waste and by-products, biogas from landfill, sewage, municipal solid waste (MSW) and black liquor from the pulp and paper industry. Depending on the nature of the feedstock, different technologies can be used, including pyrolysis, liquefaction and gasification.

For solid bio-based feedstocks, the technologies are similar to those used for converting coal to methanol, involving gasification to produce syngas, followed by methanol synthesis. Animal manure undergoes a similar process but first must be converted to biogas, then reformed into syngas, and finally synthesized into methanol. Due to the high cost and inefficiency of transporting bulky biomass with low energy density, one potential solution is converting it into a more manageable liquid intermediate through fast pyrolysis, producing a substance known as biocrude.

Biogas produced from wastewater treatment plants through methanogenesis can also be used to produce methanol in the same manner as natural gas. The use of anaerobic digesters to treat industrial wastewater has rapidly gained popularity. However, in integrated installations, biogas is primarily used to generate electricity or heat.

It’s important to note that agricultural biomass has limitations for bio-methanol production. Non-food crops grown specifically for energy would have to be cultivated on a large scale to produce significant amounts of bio-methanol. This could lead to an increase in overall greenhouse gas emissions if these crops were not grown in a sustainable manner.

Sustainable e-methanol from Carbon Capture and Utilization (CCU) or Direct Air Capture (DAC)

Another innovative source of methanol is carbon dioxide. By capturing and recycling carbon dioxide, we can produce methanol, dimethyl ether, and related products using alternative energy sources. Produced through a Power-to-X technology, e-methanol is considered an electro-fuel (e-fuel). Chemical recycling of carbon dioxide into methanol is a promising new approach typically using catalytic hydrogenation methods to convert carbon dioxide into e-methanol. This process can then be extended to produce synthetic hydrocarbons and other products, utilizing hydrogen obtained through water electrolysis.

In the future, methanol produced efficiently from atmospheric carbon dioxide and hydrogen derived from water has the potential to replace oil and gas; however, significant developments are needed before this becomes an economically viable alternative. Sustainable e-methanol can serve as a convenient energy storage medium, a suitable fuel, a chemical raw material for synthetic hydrocarbons and their products, and even for protein production. Capturing and chemically recycling carbon dioxide could transform it into a valuable, renewable and inexhaustible carbon source for the future.

The methanol economy

The concept of a “methanol economy” centers on using methanol as a renewable and clean energy source. (To further explore this topic, see the book “Beyond Oil and Gas: The Methanol Economy” by Alain Goeppert, George A. Olah, G.K. Surya Prakash discusses the concept and ongoing development of using methanol as a transportation fuel, energy storage medium, and chemical raw material to replace fossil fuels. From its inception, methanol’s potential as a versatile energy carrier has become increasingly clear.

Sustainable methanol is one of the simplest low-carbon solutions to implement, especially in the chemical and transportation industries. Switching to sustainable e-methanol or renewable bio-methanol would help reduce carbon emissions and move these industries closer to achieving net zero targets.

Advancing sustainable methanol production & usage

Despite the benefits of sustainable methanol, the global methanol supply is expected to remain dominated by grey (fossil-based) methanol in the coming decades. Both the lack of investment in new technologies as well as the uncertainty around the supply-demand scenarios currently prohibit the scale-up and broad utilization of sustainable methanol as a feedstock. Identifying pathways to bolster sustainable methanol will be key to enable the production of more sustainable chemicals, enabling emissions reductions on the pathway to net zero.

The Global Impact Coalition, an industry-led platform for collaboration across the chemical sector, is working on this challenge in their Sustainable Methanol project. The project aims to both assess realistic supply and demand scenarios for sustainable methanol while identifying viable sourcing options and production processes.

References:

- Alain Goeppert, George A. Olah, G.K. Surya Prakash. The Methanol Economy. Willey, 2018.

- Chongming Wang, Yanfei Li, Cangsu Xu, Tawfik Badawy, Amrit Sahu, Changzhao Jiang. Methanol as an octane booster for gasoline fuels. Fuel, 2019.

- IRENA AND METHANOL INSTITUTE (2021), Innovation Outlook: Renewable Methanol, International Renewable Energy Agency, Abu Dhabi.

- Seyed Shayan Tabibian, Mahdi Sharifzadeh. Statistical and analytical investigation of methanol applications, production technologies, value-chain and economy with a special focus on renewable methanol. Renewable and Sustainable Energy Reviews, 2023.