The chemical industry is a cornerstone of the global economy, supplying essential materials and technologies that form the backbone of over 95 per cent of manufactured goods. However, it is also a major contributor to environmental challenges, accounting for approximately 6 per cent of global greenhouse gas (GHG) emissions and significant resource consumption. To drive meaningful change and lead the transition toward sustainability, collaboration among industry leaders is key going forward.

Renewable Watch had the opportunity to engage with the Global Impact Coalition (GIC), a CEO-led platform dedicated to accelerating the chemical sectors transition to a netzero and circular economy. In this interview, Charlie Tan, Chief Executive Officer and Amanda Martin, Communications Lead share GIC’s vision, strategies and key initiatives aimed at reducing emissions, promoting circularity and fostering innovation across the value chain.

What is the idea behind ? What do you aim to achieve and how do you plan to achieve your goals?

GIC is a CEO-led platform focused on enabling a netzero and circular future for the chemical industry. unites industry leaders to co-create and scale technologies and business models that reduce emissions and promote circularity across the value chain. Originally incubated by the World Economic Forum, GIC relaunched as an independent entity on November 30, 2023, strengthening its commitment to sustainable solutions and low-carbon technologies.

Founded by seven leading chemical companies (BASF, SABIC, Covestro, Clariant, LyondellBasell, Mitsubishi Chemical Group and Syensqo), GIC was formed to answer the question: can we achieve netzero goals collectively, rather than individually?

Since its , GIC has grown its membership by over 50 per cent and launched successful projects, including a breakthrough pilot, innovative R&D project and joint ventures. Looking forward, GIC aims to increase its impact by expanding globally and across the value chain, while continuing to develop new projects. Through collaboration and strategic partnerships, GIC is committed to advancing a diverse portfolio of projects aimed at reducing emissions and increasing circularity along the chemical value chain. Backed by an engaged leadership team representing collective annual revenues exceeding €300 billion, and a proven, streamlined structure to swiftly transform ideas into projects and spin-offs, GIC is on the path to make a profound and enduring global impact.

What are the climate targets of select companies that are part of your platform? How does GIC help these companies achieve their targets?

While we cannot comment on the specific climate targets of our member companies, many have publicly committed to emissions reduction and circularity goals, such as sourcing a percentage of their feedstock from recycled or biobased materials. GIC supports these objectives by advancing tangible solutions through collaborative projects that challenging to undertake individually. For instance, our automotive plastics circularity project explores new streams of waste plastic material for recycling into feedstock, aiding companies in meeting their circularity targets. Similarly, our direct conversion project focuses on identifying low-emission pathways to C2+ monomers, contributing to emissions reduction goals.

What are the key emissions reduction priorities of the chemical manufacturing companies? Which emerging technologies are they focusing on to reduce their carbon emissions?

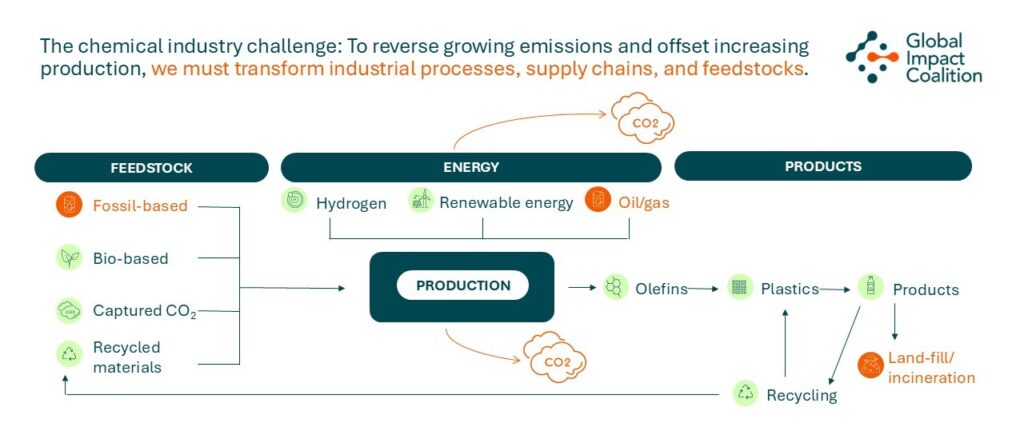

The chemical industry’s GHG emissions mainly come from energy consumption and chemical production processes. Around 60 per cent of the emissions result from burning fossil fuels to generate steam, heat and pressure required for chemical processes, while the remaining 40 per cent come from like carbon dioxide and nitrogen oxides released during chemical reactions.

To address these emission sources, chemical manufacturing companies are prioritising several key emissions reduction strategies focused on alternative energy sources and sustainable feedstocks, including:

Adoption of renewable energy sources: Transitioning from fossil fuels to renewable energy sources can drive chemical processes, including conversion, separation and purification, offering a pathway to lower emissions.

Electrification of chemical processes: Implementing electric-powered technologies, like electric steam-cracking furnaces, can significantly reduce emissions. For example, switching to electric power in steam-cracking furnaces has the potential to reduce GHG emissions by up to 90 per cent compared to conventional methods.

Utilisation of green hydrogen: Producing hydrogen through electrolysis powered by renewable energy provides a carbon-neutral feedstock and energy source for various chemical processes.

Carbon capture, utilisation and storage (CCUS): Capturing carbon emissions for utiliation in chemical processes or storage can significantly reduce the industry’s carbon footprint.

Sustainable feedstocks: Transitioning from fossil-based to renewable and bio-based feedstocks reduce carbon footprints. This include sourcing from recycled materials or captured carbon.

While operational efficiencies have achieved minor reductions in emissions, the industry now requires significant changes and innovative approaches to meet emissions reduction goals. Emerging technologies and collaborative efforts are essential to drive the substantial transformations necessary for a sustainable future.

What is the scope for electrification, green hydrogen and carbon capture to reduce emissions in this space?

Electrification, green hydrogen and carbon capture are pivotal in reducing emissions within the chemical industry: