Identify the best sources of second-generation sustainable biomass and the best conversion methods to create biobased chemicals and ensure valuable, quality end products.

To reduce greenhouse gas emissions and dependence on fossil resources, the chemical industry must transition to more sustainable feedstocks. Biomass-based alternatives offer a promising path forward—delivering 60–90% lower carbon intensity than fossil-derived counterparts and, in many cases, proving more cost-effective than other low-emissions solutions like Power-to-Chemicals. However, biomass feedstock competition, quality, and processing remain critical challenges.

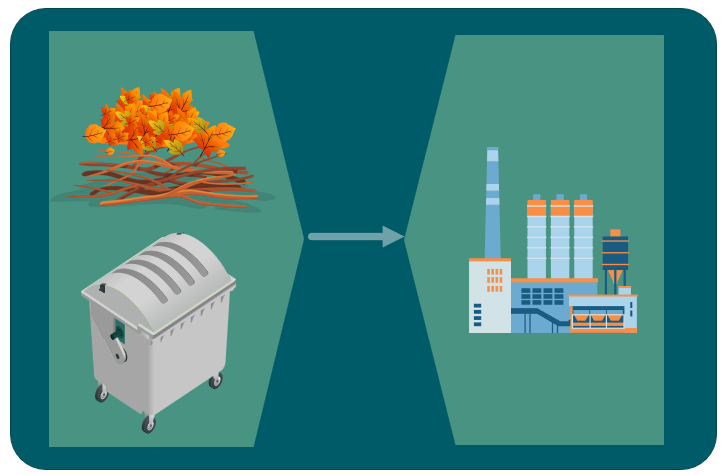

This project aims to pilot the use of second-generation (2G) biomass—such as agricultural and forestry residues or organic fractions of municipal solid waste—through conversion technologies like gasification or enzymatic hydrolysis and fermentation. By identifying viable feedstock types, evaluating technical performance, and analyzing the levelized cost of bio-based chemical production via syngas, ethanol, or methanol pathways, the project will provide actionable insights into scaling low-carbon bio-based chemicals.

GLOBAL IMPACT TOPIC: Alternative Carbon Sources

CHALLENGES TO ADDRESS:

Feedstock competition caused by high demand from competing offtake industries including aviation and energy threatens long-term availability of sustainable biomass.

VALUE OF GIC’S COLLECTIVE APPROACH:

GIC can facilitate collaboration to enable the chemical industry to secure access to suitable feedstocks through coordinated planning and sourcing opportunities.

Rising biomass feedstock prices: Biomass markets are increasingly affected by cost volatility, supply constraints, and rising demand, making it harder for companies to invest with confidence.

By combining demand signals and sharing market intelligence, GIC can help members de-risk investments, identify more stable supply channels, and pursue cost-effective procurement strategies.

Biomass feedstock quality variability: Key characteristics such as moisture content, ash composition, and chemical impurities vary widely across biomass sources, impacting processing performance and yields.

This project will help assess performance across different feedstock types—enabling better matching of feedstock to conversion technologies and reducing quality-related inefficiencies.

Lower technology readiness for certain conversion routes: Some promising biomass conversion technologies face scale-up challenges, with limited industrial demonstration to prove commercial viability.

Joint review and testing of technologies under real-world conditions can accelerate learning, reduce scale-up risk, and build investor confidence.

Hear more about this project in this video: