Working to create a more consistent and reliable supply of pyrolysis oil for use as sustainable feedstock by the chemical industry.

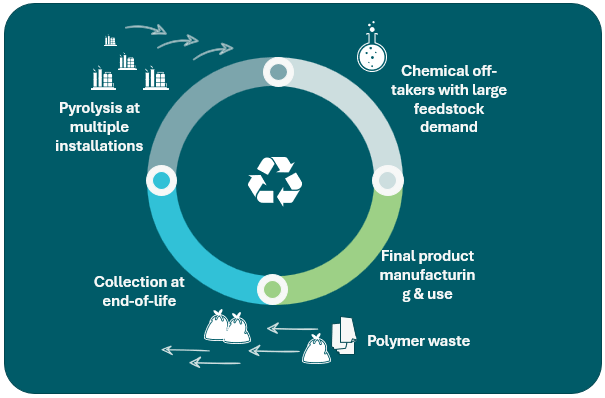

With overall low recycling rates and challenges in the collection and sorting of materials for mechanical recycling, alternative circular waste treatment solutions are needed. Pyrolysis is one of these solutions. It allows municipalities to convert waste plastics into valuable fuels, chemicals and hydrogen with lower emissions and air pollutants than incineration.

For chemical companies, pyrolysis oil is a valuable feedstock as it will help the industry move away from virgin fossil fuels and reduce greenhouse gas emissions. However, current challenges in the supply quality and availability prevent the full uptake and usage of pyoil as a viable cracker co-feed. This project will address these challenges through the development of a business intelligence platform to help improve the quality and consistency of pyrolysis oil at scale.

GLOBAL IMPACT TOPIC: Circularity of polymers

PAIN POINTS:

Fragmented volumes and intermittent supply of pyrolysis oil

UNLOCK LEVERS:

Align on clear definition of requirements & standards for pyoil steam cracker co-feed

Variability of contaminant level and fragmented sampling intensity

Provide resources and guidance to pyrolysis plants

Storage and logistics of potentially degrading material poses challenges

Facilitate transparent knowledge exchange among pyrolysis producers, investors, pyoil off-takers, enablers and waste management companies

To learn more about the challenges we are addressing with this project, check out the videos below.