Projects in progress

The following outlines some of the current prioritized projects we are advancing within multi-stakeholder working groups.

Circular Municipal Solid Waste

Map circular loops in the municipal solid waste (MSW) value chain by identifying the best recycling technologies and channelling waste into high-value circular products.

PFAS Destruction in Process Water

Identify, test and pilot the most effective, technically feasible & economically viable technologies to destruct short-chained PFAS commonly found in process water.

Sustainable Biomass Sourcing

Identify the best sources of second-generation sustainable biomass and the best conversion methods to create biobased chemicals and ensure valuable, quality end products.

Sustainable Methanol

Evaluate attractiveness to jointly develop a waste gasification–based sustainable methanol supply chain, assess preferred region, technologies, capacity and business model.

Recent projects launched

The first 18 months in the Global Impact Coalition have been busy — we have successfully advanced several projects toward spin-off or pilot with signed agreements among project members. This high rate of spin-off is testament to our clear way of working at the GIC and the focus and engagement of our members to develop compelling business cases.

Automotive Plastics Circularity

The Global Impact Coalition has launched the Automotive Plastics Circularity pilot together with eight global leaders in the chemical and recycling industries—BASF, Covestro, LG Chem, LyondellBasell, Mitsubishi Chemical Group, SABIC, SUEZ, and Syensqo. This groundbreaking pilot will address the critical challenge of recycling plastics from End-of-Life Vehicles (ELVs) by optimizing the dismantling, shredding and sorting processes, gaining access to specific polymer feedstocks for the chemical industry to increase recycling.

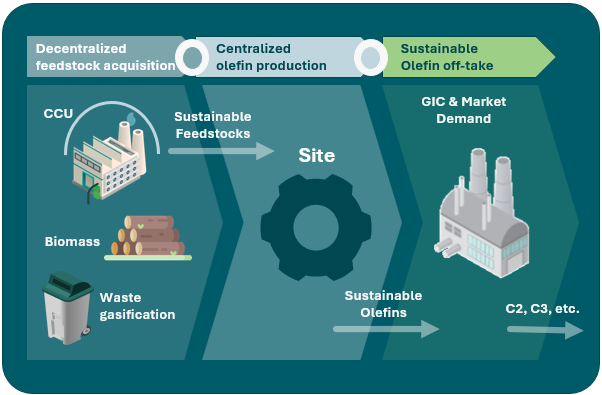

Sustainable Olefins

The GIC announces a spin-off structure to advance its Sustainable Olefins project. Starting with a feasibility study, this marks the first step toward exploring a new methanol-based route to electro-Sustainable Aviation Fuel (e-SAF) and low-carbon chemicals in Europe.

A group of GIC member companies have joined forces to evaluate the technical and economic potential of using methanol-to-olefins (MTO) technology as a sustainable alternative to conventional fossil-based production processes.

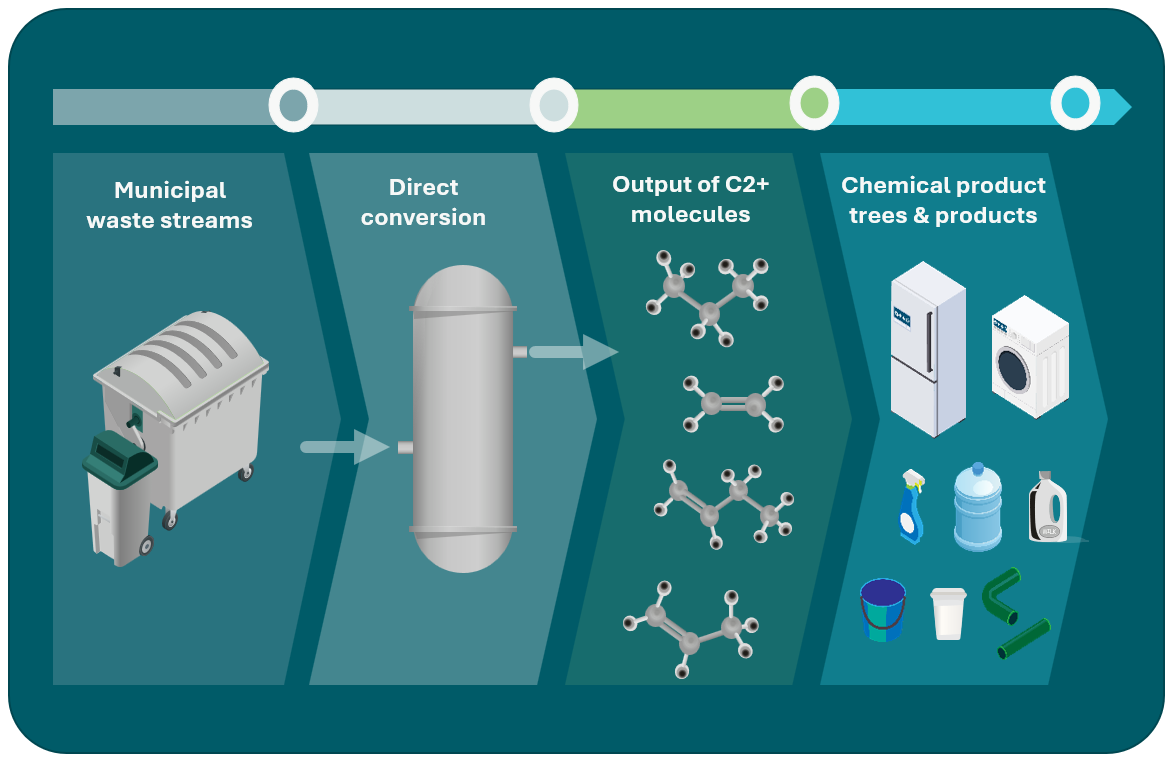

Direct Conversion research collaboration with ETH Zurich Scientists

This is a strategic research collaboration with scientists from ETH Zurich and five GIC member companies: BASF, Clariant, Covestro, LyondellBasell, and SUEZ. The aim of this collaboration is to explore synergies between traditional chemical processes and emerging technologies that convert waste into circular chemicals, specifically focusing on the direct conversion of waste into chemicals in a more sustainable approach. Direct conversion is a promising technology that transforms complex waste streams into valuable C2+ chemical compounds—such as ethylene and propylene—through gasification.

Previous projects launched

With several years of experience from our previous life as the Low Carbon Emitting Technologies platform under the World Economic Forum, we already have successfully developed and spun-off several high-impact projects. These projects are proof of the power of collaboration to drive down carbon emissions and advance towards a circular economy.

The R&D Hub for Plastic Waste Processing

The R&D Hub works to develop new technologies (with low TRL) for plastic waste processing with a lower carbon footprint and greater levels of polymer recycling. This private sector-driven project addresses the real-life technical challenges of plastic waste processing, working on problems encountered in both mechanical and chemical recycling routes. The first four projects focus on sensing, polymer/inorganics separation at mm and µm-scale, and enhanced solvolysis for composite recycling. The project is supported by BASF, Covestro, Dow, LyondellBasell, Mitsubishi Chemical Group, SABIC and Syensqo.

Since its creation, the R&D Hub is managed by our partner TNO. Learn more here. Listen to a WEF Radio Davos podcast on the recycling challenges we are working to address here.

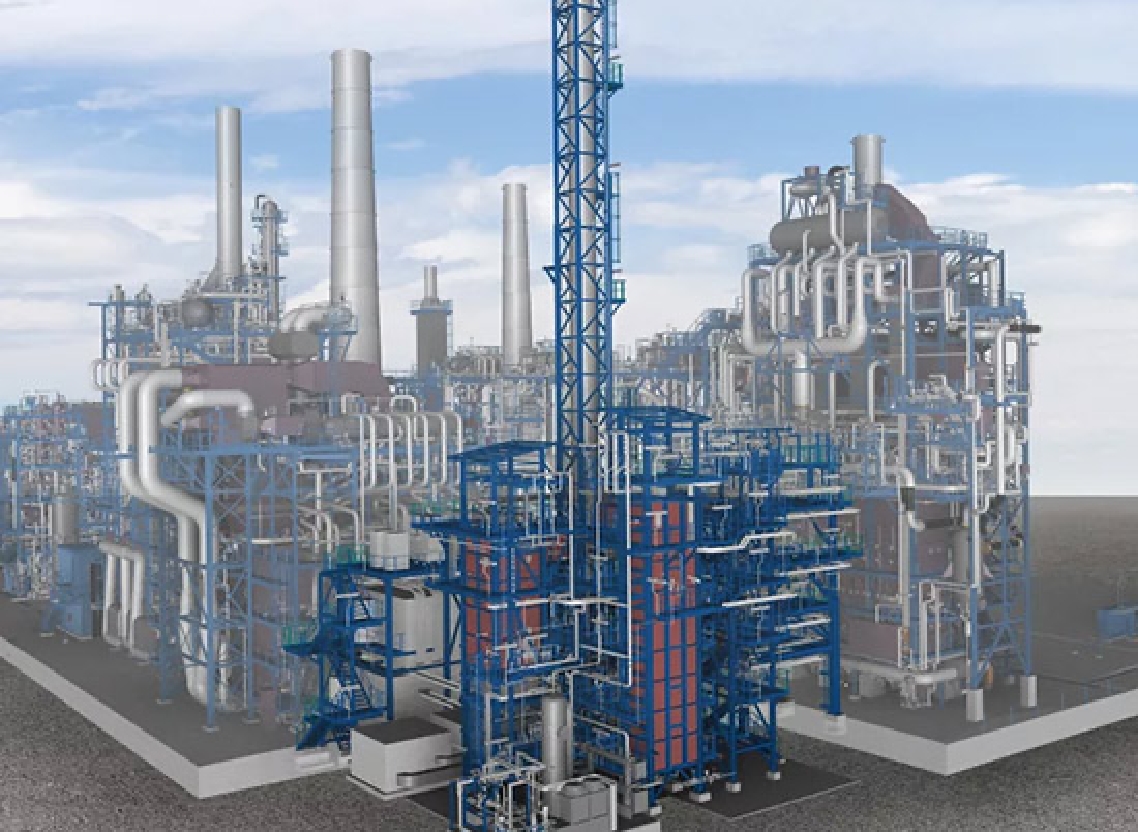

The electrically heated steam cracker furnace

This is a collaboration between member companies BASF and SABIC with engineering firm Linde. Construction of the world’s first demonstration plant for large-scale electrically heated steam cracker furnaces is in full swing. By using electricity from renewable sources instead of natural gas, the new technology has the potential to drastically reduce carbon emissions of one of the most energy-intensive production processes in the chemical industry by at least 90% compared to technologies commonly used today.

Find out more from Global Impact Coalition members BASF and SABIC.

Our Global Impact Topics

All our projects at the GIC address one of 4 Global Impact Topics based on the industry’s biggest challenges to drive down emissions and promote circularity.

- Reduce GHG emissions

- Increase Circularity

- Utilize alternative

carbon sources - Do no harm